Unlocking the Secrets: Galvanised Trailer Construction Unraveled

Understanding Galvanised Trailers

Galvanised trailers have gained popularity in various industries due to their durability, strength, and resistance to corrosion. In this section, we will provide an introduction to galvanised trailers and discuss the benefits they offer.

Introduction to Galvanised Trailers

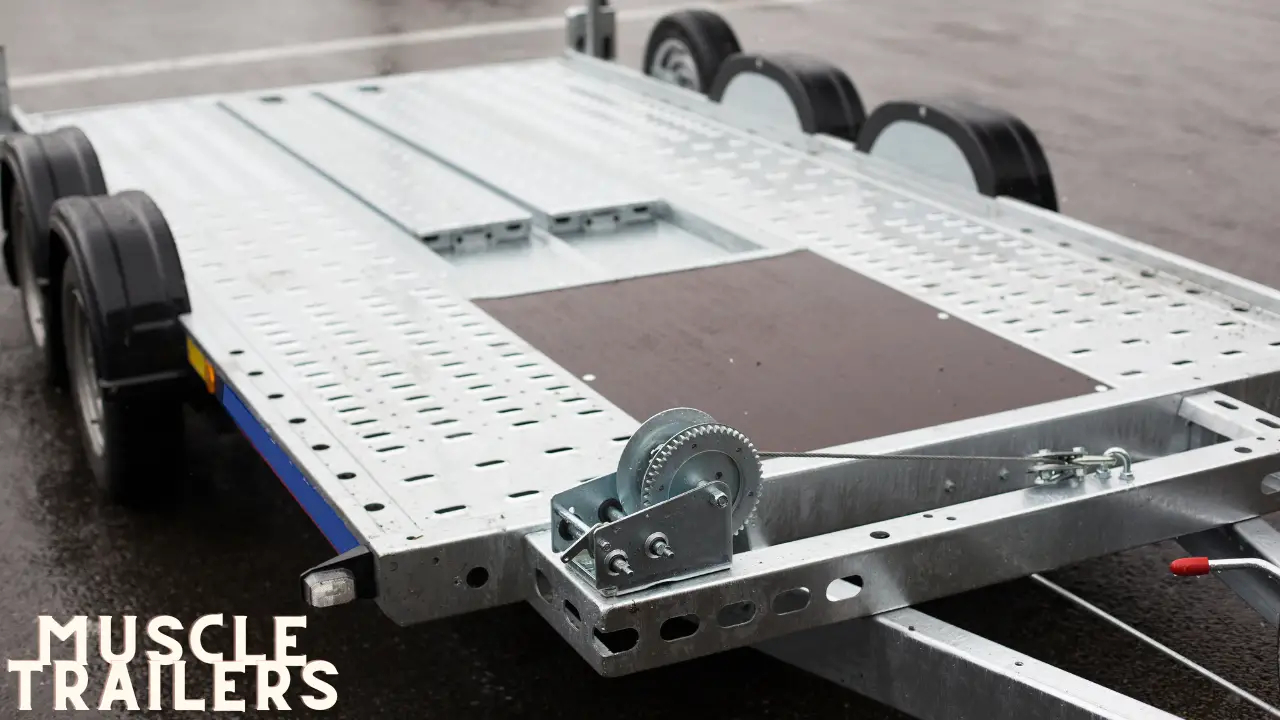

Galvanised trailers are trailers that have undergone a galvanisation process to enhance their durability and protect them from rust and corrosion. Galvanisation involves coating the trailer’s steel components with a layer of zinc, creating a barrier that prevents moisture and other corrosive elements from reaching the underlying metal. This process significantly extends the lifespan of the trailer and ensures it remains in excellent condition, even when exposed to harsh environmental conditions.

Galvanised trailers are widely used in various industries, including construction, agriculture, and transportation. They are available in a range of sizes and configurations to suit different needs, from small utility trailers to large flatbed trailers. The versatility, strength, and longevity of galvanised trailers make them a reliable choice for businesses and individuals requiring a robust transportation solution.

Benefits of Galvanised Trailers

- Corrosion Resistance: The primary advantage of galvanised trailers is their exceptional resistance to rust and corrosion. The zinc coating acts as a protective barrier, preventing moisture, salt, and other corrosive substances from reaching the underlying steel. This resistance to corrosion ensures that the trailer remains structurally sound and maintains its aesthetic appeal for an extended period, even when exposed to challenging environments.

- Strength and Durability: Galvanised trailers are known for their strength and durability. The galvanisation process enhances the structural integrity of the trailer by reinforcing the steel components. This makes galvanised trailers capable of withstanding heavy loads, impacts, and rough terrains without compromising their performance or longevity. The robust construction ensures that the trailer can endure the demands of daily use and provide reliable transportation for years to come.

- Low Maintenance: Galvanised trailers require minimal maintenance compared to trailers made from untreated steel or other materials. The zinc coating effectively protects the trailer from corrosion, reducing the need for frequent repairs or repainting. Routine maintenance primarily involves regular cleaning to remove dirt and debris, ensuring the trailer remains in optimal condition. For more information on maintaining and caring for galvanised trailers, refer to our article on galvanised trailer maintenance.

- Cost-Effective: While the initial cost of a galvanised trailer may be slightly higher than that of trailers made from other materials, the long-term cost benefits outweigh the initial investment. The durability and resistance to corrosion of galvanised trailers result in reduced repair and maintenance costs over time. Additionally, the extended lifespan of these trailers eliminates the need for frequent replacements, making them a cost-effective choice for businesses and individuals seeking a reliable transportation solution.

Galvanised trailers offer a range of benefits, from corrosion resistance to strength and low maintenance requirements. Whether you need a galvanised boat trailer or a galvanised utility trailer, these trailers provide a durable and reliable solution for your transportation needs.

Galvanised Trailer Construction

When it comes to galvanised trailers, understanding the construction process is essential to appreciate their durability and longevity. In this section, we will explore the concept of galvanisation, the galvanising process itself, and the various components that make up a galvanised trailer.

What is Galvanisation?

Galvanisation is a process that involves applying a protective zinc coating to steel or iron to prevent corrosion. The zinc coating acts as a sacrificial layer, providing a barrier between the metal substrate and the corrosive elements in the environment. This protective layer helps to extend the lifespan of the trailer, making it more resistant to rust and other forms of degradation.

The Galvanising Process

The galvanising process typically involves three main steps: preparation, galvanising, and inspection.

- Preparation: Before galvanisation, the trailer components undergo thorough cleaning to remove any dirt, grease, or surface impurities. This is crucial to ensure proper adhesion of the zinc coating. The cleaning process often involves a combination of chemical cleaning, pickling, and rinsing.

- Galvanising: Once the components are clean, they are immersed in a bath of molten zinc. The high temperature of the zinc bath allows the zinc to bond with the surface of the steel or iron, creating a metallurgical bond. This bond ensures that the zinc coating remains firmly attached to the metal substrate.

- Inspection: After galvanisation, the trailer components undergo a series of quality checks to ensure the integrity of the zinc coating. These inspections may include visual inspections, thickness measurements, and adherence tests. Any defects or imperfections are identified and addressed to meet the required standards.

By undergoing the galvanising process, the trailer components are protected from the corrosive effects of moisture, salt, and other environmental factors. This makes galvanised trailers highly durable and suitable for various applications.

Galvanised Trailer Components

A galvanised trailer consists of several key components, each of which plays a crucial role in its overall construction and functionality. Some common components include:

- Frame: The frame forms the structural backbone of the trailer. It provides support and stability, ensuring the trailer can withstand the weight and stress of the load.

- Axles: Axles are responsible for supporting and distributing the weight of the trailer and its cargo. They play a crucial role in the trailer’s towing capacity and overall performance.

- Coupler: The coupler connects the trailer to the towing vehicle. It allows for secure attachment and ensures a safe towing experience.

- Suspension: The suspension system helps to absorb shocks and vibrations while providing a smoother ride. It contributes to the overall comfort and stability of the trailer.

- Wheels and Tires: The wheels and tires are essential for the trailer’s mobility. They provide traction, support the weight of the trailer, and enable smooth movement on various terrains.

- Lights and Wiring: Lighting and wiring systems are crucial for visibility and safety. They include brake lights, turn signals, and other indicators that comply with road regulations.

- Bed or Deck: The bed or deck is the surface on which the cargo is placed. It should be sturdy and able to support the weight of the load.

By understanding the construction and components of galvanised trailers, you can make informed decisions when choosing the right trailer for your needs. Whether you’re considering galvanised boat trailers, galvanised utility trailers, or any other type, the galvanised construction provides durability, corrosion resistance, and a longer lifespan. Regular maintenance and care, such as cleaning, rust prevention, and inspection, will help to ensure the trailer remains in optimal condition for years to come.

Strength and Durability

When it comes to galvanised trailers, their strength and durability are key factors that make them a popular choice among small business owners, transport companies, and trailer enthusiasts. The use of galvanised steel in the construction of these trailers provides several advantages that contribute to their robustness and longevity.

Advantages of Galvanised Steel

Galvanised steel, a material coated with a layer of zinc, offers exceptional strength and resilience. This makes it an ideal choice for constructing trailers that can withstand heavy loads, rough terrains, and various weather conditions. Here are some advantages of using galvanised steel in trailer construction:

- Corrosion Resistance: The zinc coating on galvanised steel acts as a protective barrier, shielding the steel from corrosion caused by moisture, chemicals, and exposure to the elements. This corrosion resistance significantly extends the lifespan of the trailer, reducing the need for frequent repairs or replacements.

- Impact Resistance: Galvanised steel is known for its high impact resistance, making it less susceptible to dents, scratches, and deformation. This durability ensures that the trailer can withstand the rigors of transportation, including bumps, vibrations, and heavy loads.

- Longevity: The combination of galvanised steel’s corrosion resistance and impact resistance results in a trailer that can withstand the test of time. Galvanised trailers have a longer lifespan compared to trailers made from other materials, providing long-term value and cost-effectiveness.

Corrosion Resistance

One of the primary benefits of galvanised steel is its excellent corrosion resistance. The zinc coating acts as a sacrificial layer that corrodes preferentially to the underlying steel when exposed to moisture or corrosive substances. This sacrificial corrosion process helps protect the steel, preventing rust and deterioration. As a result, galvanised trailers are highly resistant to rust, even in harsh environments or when exposed to road salt.

Impact and Load Capacity

Galvanised trailers are designed to handle heavy loads and endure the stresses of transportation. The inherent strength of galvanised steel, combined with its impact resistance, allows these trailers to withstand the bumps, vibrations, and impacts encountered on the road. Whether it’s carrying construction materials, landscaping equipment, or other heavy items, galvanised trailers provide the durability needed for safe and reliable transportation.

To ensure optimal performance, it’s important to choose a galvanised trailer that suits your specific needs. Consider factors such as the trailer’s weight capacity, size, and intended use. Additionally, regular maintenance and care, including cleaning, rust prevention, and inspection, will help prolong the lifespan and maintain the durability of your galvanised trailer. For more information on maintenance and care, refer to our article on galvanised trailer maintenance.

The strength and durability of galvanised trailers make them a reliable choice for various applications. Whether you need a utility trailer, box trailer, or flatbed trailer, the use of galvanised steel ensures that your trailer can handle the demands of your specific hauling needs.

Common Galvanised Trailer Types

Galvanised trailers are available in various types, each designed to serve specific purposes and cater to different hauling needs. Whether you require a utility trailer, a box trailer, or a flatbed trailer, galvanised construction ensures durability and protection against corrosion. Let’s explore these common types of galvanised trailers:

Utility Trailers

Utility trailers are versatile and widely used for transporting a variety of goods and equipment. They feature an open design with a flatbed or low sides, allowing for easy loading and unloading. Utility trailers are commonly used in industries such as landscaping, construction, and agriculture.

These trailers come in different sizes and weight capacities to accommodate various hauling requirements. With their galvanised construction, utility trailers offer robustness, longevity, and resistance to rust and corrosion. They are an excellent choice for those seeking a reliable and durable hauling solution. Explore our selection of galvanised utility trailers for more information.

Box Trailers

Box trailers, also known as enclosed trailers, provide a secure and weatherproof solution for transporting goods. They feature solid walls and a roof, protecting the cargo from the elements during transportation. Box trailers are commonly used for moving furniture, appliances, and other valuable items.

Galvanised box trailers offer the added benefit of corrosion resistance, ensuring that the trailer remains in excellent condition even when exposed to harsh weather conditions. These trailers are available in different sizes and configurations to suit various hauling needs. Discover our range of galvanised box trailers for options that combine durability and functionality.

Flatbed Trailers

Flatbed trailers feature a completely flat, open platform without any sides or roof. This design allows for easy loading and transportation of oversized or irregularly shaped cargo. Flatbed trailers are commonly used in the construction, transportation, and agricultural industries.

Galvanised flatbed trailers provide exceptional strength and durability, making them capable of withstanding heavy loads and demanding conditions. The galvanised coating ensures resistance to rust and corrosion, extending the lifespan of the trailer. If you’re in need of a reliable hauling solution for large or irregular loads, our selection of galvanised flatbed trailers offers a range of options to suit your needs.

When considering a galvanised trailer, it’s important to assess your specific requirements and select the type that best suits your hauling needs. Whether you choose a utility trailer, a box trailer, or a flatbed trailer, the galvanised construction ensures durability, longevity, and resistance to corrosion. Browse our range of galvanised trailers for sale to find the best option for your hauling endeavors.

Maintenance and Care

To ensure the longevity and optimal performance of your galvanised trailer, regular maintenance and care are essential. By following a few simple steps, you can keep your trailer in excellent condition for years to come. Here are three key aspects of maintenance and care: cleaning and washing, rust prevention, and inspection and repairs.

Cleaning and Washing

Regular cleaning and washing of your galvanised trailer will help remove dirt, grime, and debris that can accumulate during use. It’s important to clean both the interior and exterior of the trailer. Start by rinsing the trailer with water to remove loose particles. Then, use a mild detergent or soap solution and a soft brush or sponge to scrub the surfaces. Pay close attention to areas that are prone to buildup, such as the underside and wheel wells.

After cleaning, rinse the trailer thoroughly with water to remove any soap residue. This step is crucial as soap residue can contribute to corrosion over time. Once the trailer is clean and dry, consider applying a protective wax or coating to enhance its resistance to elements and maintain its appearance.

Rust Prevention

Galvanised trailers are designed to resist rust and corrosion, thanks to the galvanisation process. However, it’s still important to take preventive measures to prolong the life of your trailer. Regularly inspect your trailer for any signs of damage to the galvanised coating, such as scratches or chips. If you notice any exposed metal, promptly repair it with a suitable galvanised paint or coating to prevent rust formation.

Additionally, avoid exposing your trailer to prolonged periods of moisture or harsh chemicals, as these can compromise the galvanised coating. If you use your trailer near saltwater environments, it’s especially important to rinse it thoroughly with freshwater after each use to remove any salt residue. For more detailed guidelines on rust prevention, consult our article on galvanised trailer maintenance.

Inspection and Repairs

Regular inspection of your galvanised trailer is crucial to identify any potential issues or areas that require repairs. Inspect the trailer’s frame, components, and fasteners for signs of wear, damage, or loosening. Pay attention to areas that are more prone to stress, such as the hitch, suspension, and axles. If you notice any abnormalities or concerns during the inspection, address them promptly to prevent further damage or potential safety hazards.

When it comes to repairs, it’s advisable to consult a professional if you are unsure of the proper techniques or materials. They can provide guidance on repairing the galvanised coating, replacing components, or resolving any structural issues. Remember, proper repairs and maintenance play a vital role in ensuring the safety, durability, and performance of your galvanised trailer.

By incorporating these maintenance and care practices into your routine, you can protect your galvanised trailer from damage, extend its lifespan, and maintain its functionality. Regular cleaning, rust prevention, and thorough inspections will help you identify any potential issues early on, allowing for timely repairs and ensuring that your trailer remains in top condition for all your hauling needs.

Author

I am Rahatul Ashiq Tamal. Another author of Muscle Trailers. Muscle Trailers is a well-known trailer brand in Sydney, Melbourne & Adelaide

How to Mount a Spare Tire on Your Trailer: A Simple Step-by-Step Guide

Trailer service centers receive over 1 million phone calls and 1.3 million emails each year about trailer maintenance problems....

How to Fix RV Roof Leaks: Simple Roof Leak Detection Guide for Beginners

Did you know DIY RV roof repairs can cost under $50? But undetected leaks could lead to substantially higher repair...

Starting a Food Truck Business in Australia: From Trailer Selection to Launch

The Australian mobile food market has evolved into a billion-dollar industry. This makes a food truck...