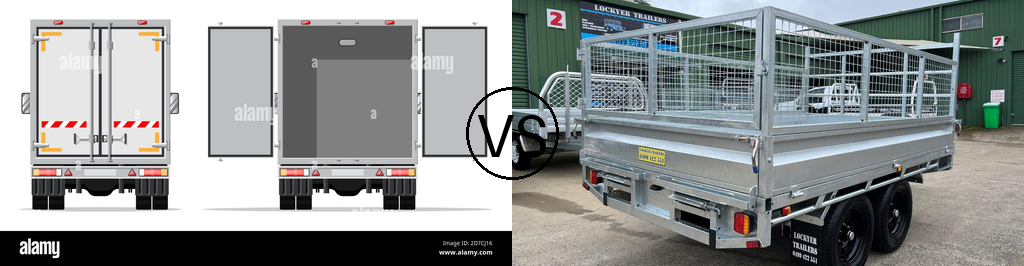

Box Trailers vs Flatbed Trailers: Which Gives More Value in 2025?

The choice between box and flatbed trailers can greatly affect your investment’s long-term value. Box trailers deliver impressive capabilities. Top models handle up to 3.2 tons and provide built-in protection through features like mesh cages that keep pests away.

Both categories of heavy duty trailers bring unique advantages. Box trailers excel with their sturdy, lightweight construction and reliable performance. Flatbed trailers give you versatility to handle different loading requirements. Looking ahead to 2025, your choice between these options depends on several factors.

This piece will get into both trailer types and compare everything from the original costs to how well they hold their value. You’ll learn what works best to haul construction materials or move sensitive equipment. The information will help you make a smart decision that lines up with what you need and can afford.

Understanding Box Trailers vs Flatbed Trailers

Box trailers and flatbed trailers each serve unique purposes through their basic design differences. Box trailers have a rectangular, enclosed structure with solid sides that create a contained space. Flatbed trailers feature an open platform design without sides and provide a versatile loading surface.

Key Design Differences

Box trailers’ basic construction revolves around an enclosed structure mounted on a chassis that creates a protected cargo area. These trailers have rear doors or tailgates to access cargo easily. Flatbed trailers consist of a sturdy platform that you can fit with removable headboards or H frames based on your needs. Box trailers range in size from 6 x 4 up to 10 x 6. The tandem axle versions go from 8 x 4 up to 20 x 6.

Load Capacity Comparison

Each trailer type excels at different load handling tasks. Box trailers work best for:

- Transporting loose materials like soil, sand, rubble, and garden waste

- Securing livestock with stock crate sides

- Organizing tools and equipment with internal compartments

Flatbed trailers show amazing versatility for oversized cargo, with sizes ranging from 8 x 6 up to 24 x 8. These trailers excel at handling industrial equipment and irregularly shaped items that won’t fit in enclosed spaces.

Weather Protection Features

Box trailers’ enclosed design shields cargo from environmental elements effectively. The original aluminum bodies help these trailers resist rust and corrosion. Their sealed structure maintains steady internal conditions and protects cargo from rain, snow, and extreme temperatures.

Box trailers also include security features with water-resistant seals around doors and openings. Manufacturers use galvanized steel or aluminum in construction to ensure long-term weather resistance. Flatbed trailers need simpler maintenance because their open design prevents moisture from building up in enclosed spaces.

Initial Investment Analysis

You’ll need to think over several cost factors to make smart financial decisions about trailer investments. Australia’s trailer industry has 531 businesses, and the market keeps growing.

Purchase Price Comparison

A simple box trailer costs around AUD 3,057.98, which works well for regular transport needs. High-end models with all the bells and whistles can cost up to AUD 30,579.80. The price differences come from size variations, quality of materials, and how they’re built.

The market has seen some changes lately. Revenue dropped by 0.4% to AUD 5.05 billion through 2024-25. This led to dealers competing hard on prices, which is great news if you’re looking for specific models.

Additional Equipment Costs

The base price is just the start. Here’s what else you might need to add:

- Weatherproof lockable lids and LED tail lights

- Gas strut assisted mechanisms

- Spare wheel mounts and jockey wheels

- Stone guards and toolboxes to boost utility

You can also add custom features like extended drawbars, water tanks, and specialized racks that affect the final price significantly. These extras should match your transport needs and how you plan to use the trailer.

Insurance Considerations

The trailer’s value and use determine what insurance you need. Simple utility trailers can often be added to your home or car insurance. More expensive trailers need their own policies that cover:

- Complete protection against theft, fire damage, and accidents

- Third-party liability coverage

- Protection during storage and transportation

Your insurance costs change based on trailer size, how often you use it, and time spent on the road. Some policies also cover cargo protection and roadside assistance to give you complete peace of mind.

Versatility and Applications

The right trailer choice depends on how you plan to use it in different industries. Box trailers and flatbed trailers each have their own strengths that make them perfect tools for specific jobs and sectors.

Common Use Cases for Box Trailers

Box trailers shine in residential and commercial moving jobs. These enclosed units keep household items, furniture, and sensitive equipment safe during transport. DIY enthusiasts and home renovators find these trailers are the quickest way to move building materials and tools without making multiple trips. These trailers are a great way to get ready for camping adventures too. They safely carry bikes, BBQs, and camping gear while protecting them from bad weather.

Flatbed Trailer Applications

Flatbed trailers work well in many different sectors. Construction companies use these platforms to move heavy machinery like skid steers, bulldozers, and excavators. Farmers count on flatbed trailers to transport hay bales, field equipment, and bulk materials between locations. Manufacturing plants use flatbed trailers to move steel coils, machinery parts, and industrial equipment.

Industry-Specific Requirements

Each industry faces its own set of rules and operational needs. Australian RVS legislation requires manufacturers and importers of trailers with a total trailer mass (ATM) of 4.5 tons or less to get specific approvals before selling. Companies that supply more than 4 low ATM trailers per year must have a vehicle type approval.

Construction companies just need trailers that can handle:

- Piping and rebar materials

- Large concrete blocks

- Prefabricated buildings

- Steel frames and frameworks

Farm operations need special features to move livestock feed, farming machinery, and fresh produce to markets. Many flatbed trailers now come with removable sides or container pins to fit different load types. Oil and gas companies rely on heavy-duty flatbed trailers to move rig components between sites.

Both types of trailers can be customized to fit specific industry needs. Box trailers work well with internal shelving and climate control systems for sensitive cargo. Flatbed trailers can be modified with heavy-duty flooring and extra tie-down points to secure special loads.

Maintenance and Operating Costs

The way you manage to keep your trailer determines how long it will last and how well it works. Flatbed trailers show lower maintenance needs because of their simple design. They lack enclosed spaces where moisture and dirt could build up.

Regular Maintenance Requirements

Box trailers need complete maintenance routines. This is especially true around roof and door seals to protect both the trailer and cargo. These enclosed units need regular checks of:

- Interior wear patterns

- Seal integrity

- Structural components

- Chassis condition

Flatbed trailers have simpler cleaning processes because their open design leaves no hidden corners where debris could collect. The maintenance focus shifts to the platform surface and support structure instead of enclosed spaces.

Repair Frequency and Expenses

Different trailer types show clear cost differences in their repair patterns. Air-ride suspension maintenance costs reach about AUD 1,376.09 over ten years. Spring-ride systems only need AUD 366.96 for the same timeframe. A well-maintained trailer can last about 15 years.

Steel trailers need extra care to stop rust and corrosion, though galvanizing helps reduce these problems. Aluminum and composite materials resist corrosion better and need less maintenance over time.

Fuel Efficiency Impact

Aerodynamic features are vital for fuel consumption. Studies show that aerodynamic improvements can cut fuel consumption by 3.0% in long-haul operations. Lightweight trailers show even better results with a 17.7% improvement in fuel economy.

Combining aerodynamic features with lightweight construction gives the best results. These changes can reduce fuel consumption by about 20.2% during long-haul operations. Results vary based on driving conditions:

- City Center driving improves around 17.5%

- Motorway cruising at 84 km/h gets up to 22.4% better efficiency

Trailer skirts cost between AUD 1,528.99 and AUD 4,586.97 upfront but can improve fuel efficiency by 1% to 5%. Fleets that cover 120,000 miles yearly per truck could save AUD 3,218.52 per vehicle annually.

Storage and Handling

Your trailer’s storage and handling capabilities will determine how useful box trailers and flatbed trailers are. Learning about these features helps you streamline processes and keep your trailer in good condition.

Space Requirements

Different trailer types need different storage solutions. Box trailers need dedicated indoor or covered storage spaces that protect their enclosed structure and keep weatherproof seals intact. You have three main storage options:

- Basic outdoor parking with security features

- Covered storage protecting against precipitation

- Fully enclosed units offering complete weather protection

Specialized storage facilities give you 24/7 access and surveillance systems that keep your trailer secure and easy to access. Flatbed trailers are more flexible with storage needs because their open design reduces moisture buildup concerns.

Ease of Maneuvering

The length of your trailer has a big effect on how it handles. Medium-length trailers between 25-30 feet give you the best balance of maneuverability and utility. Your tow vehicle and trailer create unique steering dynamics – the trailer moves opposite to your front wheels’ direction.

Expert operators suggest these tips for better control:

- Drive slower for better control

- Use mirrors to watch your trailer position

- Make gradual steering movements for smooth transitions

- Practice in open spaces to improve your handling skills

Your wheel-base length changes your turning radius and stability. Longer wheel-bases give you better stability but need wider turns. Shorter configurations let you make tighter turns but are less stable at highway speeds.

Loading/Unloading Efficiency

Flatbed trailers make loading easy with multiple entry points from sides and top. This design works great for farm operations that need quick loading of equipment and produce. Box trailers offer structured loading through rear access points – perfect for organized cargo management.

Load positioning changes how your trailer handles. Weight distribution is vital – about 60% of the total weight should sit forward of the center axle. You should check your trailer’s attitude right after loading. The drawbar should stay level or point slightly down.

Good loading practices affect safety and performance. Your loads must stay within specific limits – no more than 150mm beyond the trailer’s width or 2.5m overall width. Oversized items need proper marking, and anything sticking out more than 1.2m needs red flags at least 300mm square.

Long-Term Value Retention

Quality construction is the foundation that determines a trailer’s lasting worth, no matter its age or style. Let’s look at what makes trailers a solid long-term investment.

Depreciation Rates

Different trailer types lose value at different rates. Aluminum trailers keep their value longer, and enclosed models can last up to 25 years with good maintenance. The biggest drop in value happens in the first year, mostly hitting cheaper models that aren’t built to last.

The right materials make a big difference in slowing down value loss:

- Aluminum construction resists corrosion

- Enclosed underbelly systems protect vital components

- Non-wood framing adds years to the life

Resale Value Comparison

Box trailers sell better in certain markets because they’re versatile and protect cargo well. Flatbed trailers also hold their value since they work well for many industries. Market needs drive resale prices, and luxury models are worth 30% more after five years.

Aluminum trailers beat steel ones in the resale market. This happens because they:

- Last longer against weather damage

- Need less upkeep

- Hold up better structurally

Durability Factors

The quality of materials shapes how long a trailer lasts. Well-maintained aluminum trailers usually last 15-20 years. How often you use the trailer and its exposure to weather can affect its lifespan. Motivated trailer owners see their units lasting beyond 20 years of service life.

A trailer’s strength depends on:

- Original build quality

- Regular maintenance

- Weather conditions

High-end materials are worth their higher price tag because they last longer and cost less to maintain. Good construction and proper care work together to help trailers last longer than expected. Premium models work well even after decades of use if they get the right care.

Safety and Compliance

Safety features and compliance standards are the foundations of reliable trailer operations. Modern box trailers and flatbed trailers use sophisticated security systems that protect valuable cargo and prevent theft.

Security Features

Advanced security technology has brought multiple protective measures to trailers. GPS tracking systems provide precision monitoring with five meters accuracy. These systems come with geofencing capabilities and trigger alerts when the trailer moves beyond defined boundaries.

Security components include:

- Anti-theft hitch pins with dust-resistant key entry points

- Universal coupling locks compatible with both braked and unbraked systems

- Wheel clamps that work as visual deterrents and physical barriers

- Tow ball locking devices that stop unauthorized vehicle attachment

Smart technology has improved trailer protection through remote monitoring capabilities and keyless entry systems. These innovations let owners track their assets live and are quick to react to unauthorized access attempts.

Regulatory Requirements

RVS legislation requires manufacturers to get specific approvals for trailers with a total trailer mass of 4.5 tons or less. Vehicle type approval becomes mandatory for businesses that provide more than four low ATM trailers yearly.

The Australian Design Rules (ADR) specify these requirements for trailers:

- Service brake systems for trailers exceeding 750kg

- Emergency brake activation upon trailer separation

- Independent parking brake mechanisms

Electrical systems must meet strict standards for voltage, current, and insulation. Mudguards must stop debris projection toward other vehicles while meeting specific angular requirements.

Load Securing Options

Load security works on two basic principles: containment and restraint. Containment limits the loading area, while restraint focuses on increasing friction forces between the load and surface.

Proper load distribution is a vital part of operational safety. Cargo positioned too far back can reduce semi-trailer pressure and affect tire grip and driving safety. Forward-heavy loads might overload the drive axle.

Flatbed configurations need extra attention to federal regulations. Straps that support up to 5,500 lbs secure cargo regularly, while chains and binders handle heavier loads like steel coils and farm equipment. Regular checks of securing equipment will give a safe operation that meets safety standards.

Environmental Impact

The future of trailer manufacturing depends on environmental factors. Different trailer types and their uses show clear variations in how they affect the environment.

Carbon Footprint Comparison

Trailer design directly affects fuel consumption and emissions. New aerodynamic features cut greenhouse gas emissions by 5-6% compared to standard designs. We tested natural gas-powered systems that showed a 40-50% drop in terrestrial eutrophication and acidification. These systems also reduced particulate matter and photochemical ozone formation by 10%.

Lightweight trailer designs deliver remarkable results. Modern trailers weigh less and carry more while using less fuel. A trailer moving 50,000 tons of payload over 130,000 km yearly saves about 2,400 liters of diesel. This reduction cuts carbon emissions by more than 6,000 kg CO2e.

Recyclability

Material choice is vital for environmental sustainability. Manufacturers now design products that can be recycled or reused. Their approach includes:

- Raw material selection prioritizing recyclable components

- Clean production processes minimizing harmful emissions

- Post-production waste reduction strategies

- End-of-life material recovery systems

Manufacturers have improved their processes and work with suppliers throughout the component lifecycle. Modern facilities reduce negative environmental effects more effectively than traditional manufacturing methods.

Eco-friendly Features

New trailer designs feature many environmental breakthroughs. Manufacturers have cut their carbon footprints from 154tCO2e to 8.61tCO2e in manufacturing processes – a 94% reduction. Modern facilities now use:

- Inverter welders for energy efficiency

- Wastewater treatment systems

- LED lighting throughout facilities

- Lean manufacturing processes minimizing scrap metal

Australia’s transport industry ranks as the third-largest CO2 emitter and could become the highest by 2030. Manufacturers have responded by adopting green solutions in all business areas. They recycle wood pallets and metal, and test alternative lubricants like beeswax instead of canola oil.

Sustainability efforts go beyond manufacturing. Companies work together with universities to find ways to reduce carbon footprints. These strategic collaborations focus on developing clean production processes. They aim to eliminate harmful emissions of gasses, liquids, and solid substances while saving energy, heat, water, and raw materials.

Manufacturers assess environmental effects in five key areas: climate change, particulate matter, ozone photochemical formation, terrestrial eutrophication, and acidification. These metrics help them improve environmental performance. Trailers must meet strict ecological standards while maintaining efficiency.

Comparison Table

| Feature | Box Trailers | Flatbed Trailers |

|---|---|---|

| Simple Design | Rectangular enclosed structure with solid sides | Open platform design without sides |

| Size Range | 6×4 to 10×6 (single axle) 8×4 to 20×6 (tandem axle) | 8×6 up to 24×8 |

| Weather Protection | Superior protection with sealed structure and water-resistant seals | Limited weather protection due to open design |

| Main Applications | – Transporting loose materials – Livestock with stock crates – Tools and equipment storage – Residential moving | – Heavy machinery transport – Construction equipment – Agricultural equipment – Oversized cargo |

| Starting Price | From AUD 3,057.98 | Not mentioned |

| Maintenance Requirements | Higher maintenance needs: – Regular seal inspection – Interior wear checks – Moisture control | Lower maintenance needs due to simple design and lack of enclosed spaces |

| Storage Requirements | Requires dedicated indoor/covered storage | More flexible storage options |

| Loading Access | Limited to rear access points | Multiple entry points from sides and top |

| Material Options | Aluminum or steel construction | Not specifically mentioned |

| Lifespan | Up to 25 years (aluminum construction) | 15-20 years (with proper maintenance) |

Conclusion

Box trailers and flatbed trailers each have unique advantages that will extend well into 2025 and beyond. Our complete analysis shows box trailers do an excellent job protecting cargo from weather while offering better security features. These enclosed units are a great choice for residential moving, tool storage, and transporting sensitive equipment.

Flatbed trailers shine because of their versatility and easy maintenance. The open design lets you load cargo from any angle, which works perfectly for construction materials, heavy machinery, and oversized loads. Their simple structure means lower maintenance costs and fewer problems down the road.

Flatbed trailers cost less upfront, though box trailers hold their resale value better. Both trailer types last longer with aluminum construction, and proper maintenance can extend their life beyond 20 years. Safety features and compliance with regulations play a vital role, as modern designs now include advanced security systems that meet strict Australian Design Rules.

The environmental aspect needs careful thought. Newer models have improved fuel efficiency and reduced emissions significantly. Manufacturers focus on recyclable materials and eco-friendly production, which has cut carbon footprints by up to 94% in some cases.

Your choice between these trailer types depends on how you’ll use it, your budget, and long-term value expectations. Box trailers work best for users who need cargo protection and security. Flatbed trailers suit those who want maximum loading flexibility and lower maintenance costs.

FAQs

Q1. Which type of trailer is more versatile: box or flatbed? Flatbed trailers offer greater versatility due to their open design, allowing for easy loading of oversized cargo, heavy machinery, and construction equipment from multiple angles. Box trailers, while less versatile, excel in protecting cargo from the elements and are ideal for transporting loose materials, tools, and household items.

Q2. How do maintenance requirements differ between box and flatbed trailers? Box trailers generally require more maintenance due to their enclosed design, necessitating regular inspections of seals, interior wear, and moisture control. Flatbed trailers, with their simpler open structure, typically have lower maintenance needs and are easier to clean and inspect.

Q3. What is the average lifespan of a well-maintained trailer? A well-maintained trailer can last 15-20 years on average. Aluminum box trailers can potentially last up to 25 years, while properly cared for flatbed trailers often achieve a 15-20 year lifespan. Regular maintenance and proper usage significantly impact longevity for both types.

Q4. How do box and flatbed trailers compare in terms of environmental impact? Both trailer types have seen improvements in environmental impact. Modern designs incorporate aerodynamic features and lightweight materials that can reduce fuel consumption and emissions by 5-6%. Some manufacturers have reduced their carbon footprint in production by up to 94% through eco-friendly manufacturing processes and the use of recyclable materials.

Q5. What are the key safety features to consider when choosing a trailer? Important safety features for trailers include GPS tracking systems with geofencing capabilities, anti-theft hitch pins, coupling locks, and wheel clamps. Additionally, ensure the trailer meets Australian Design Rules, including proper brake systems for trailers over 750kg, emergency brake activation, and appropriate electrical systems. For flatbeds, robust load securing options are crucial for safe transportation.

Author

I am Rahatul Ashiq Tamal. Another author of Muscle Trailers. Muscle Trailers is a well-known trailer brand in Sydney, Melbourne & Adelaide

How to Mount a Spare Tire on Your Trailer: A Simple Step-by-Step Guide

Trailer service centers receive over 1 million phone calls and 1.3 million emails each year about trailer maintenance problems....

How to Fix RV Roof Leaks: Simple Roof Leak Detection Guide for Beginners

Did you know DIY RV roof repairs can cost under $50? But undetected leaks could lead to substantially higher repair...

Starting a Food Truck Business in Australia: From Trailer Selection to Launch

The Australian mobile food market has evolved into a billion-dollar industry. This makes a food truck...