Unleash the Power of Trailer Leaf Springs: Take Control of Your Hauling

Understanding Trailer Leaf Springs

Before delving into the types and functionalities of trailer leaf springs, it’s important to understand the basics. In this section, we aim to answer some fundamental questions: What are trailer leaf springs? And what makes them important for your trailer?

What Are Trailer Leaf Springs?

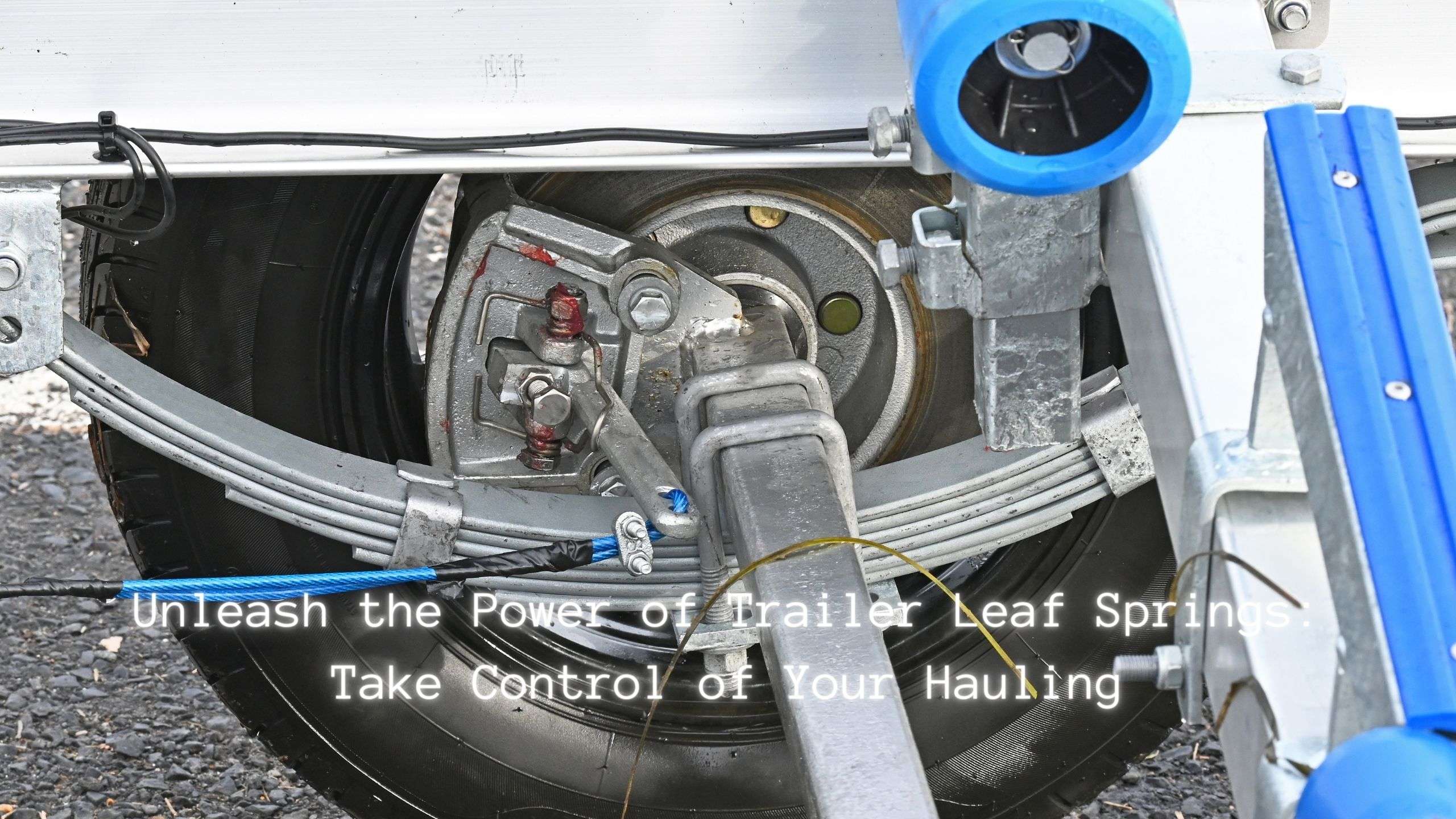

Trailer leaf springs are an integral part of a trailer’s suspension system. Leaf springs are stackable arc-shaped plates that act as shock absorbers for potholes and support vehicles’ braking systems. They are the steel components that support the weight of the trailer and absorb road shock and vibrations.

The name ‘leaf springs’ comes from the design of these components. They are made up of several thin strips of metal, called ‘leaves’, which are stacked together to form a single, curved assembly. The curvature of the leaves allows them to flex and absorb shocks, providing a smoother ride.

Importance of Trailer Leaf Springs

The significance of trailer leaf springs in a trailer’s suspension system cannot be overstated. These components play a pivotal role in supporting the weight of the trailer and helping to absorb shocks and vibrations during travel (Tow-Max). They help distribute the weight of the trailer evenly across all wheels, preventing excessive stress on individual components.

Beyond offering a smoother ride, leaf springs also improve stability and handling on uneven ground, reduce brake wear, and can even contribute to better fuel efficiency. Their overall impact on trailer performance and safety is substantial, making them a crucial part of your trailer’s setup.

As we delve further into the topic of trailer leaf springs, we’ll explore different types, their specific applications, and factors to consider when choosing the right leaf springs for your trailer. Additionally, we’ll cover maintenance tips and the role these components play in overall trailer safety. Stay tuned for more insightful information on optimising your hauling capabilities with the right trailer leaf springs.

Types of Trailer Leaf Springs

When it comes to trailer leaf springs, there are several different types to choose from, each with their own unique properties and benefits. These include steel leaf springs, composite leaf springs, and rubber leaf springs. Let’s take a closer look at each type.

Steel leaf springs

Steel leaf springs are the most common and widely used type of leaf springs for trailers. Known for their durability and strength, these springs are capable of handling heavy loads and are ideal for most standard hauling needs (Tow-Max).

Steel springs are composed of stackable arc-shaped plates that act as a shock absorber for potholes, support the vehicle’s braking system, and improve stability and handling on uneven ground. They absorb road shock, reduce brake wear, and can even improve fuel efficiency.

Composite leaf springs

Composite leaf springs, made from a combination of materials such as fibreglass and resins, offer a lighter-weight alternative to steel leaf springs. Despite their lighter weight, these springs still provide excellent strength and durability, making them a solid choice for many trailer applications.

The use of composite materials also allows these springs to be moulded into complex shapes, which can provide additional benefits in terms of load distribution and handling characteristics. If you’re looking for a more modern, lightweight solution, composite leaf springs may be the right choice for your trailer.

Rubber leaf springs

Rubber leaf springs are often used in specialised trailer applications. Known for their excellent vibration isolation and noise reduction properties, these springs provide a smoother and quieter ride compared to their steel or composite counterparts.

While not as common as steel or composite springs, rubber leaf springs can be a great choice for trailers that require a high degree of comfort and noise reduction. This can be particularly beneficial for trailers that carry sensitive or fragile cargo.

When choosing the type of leaf springs for your trailer, it’s important to consider factors such as the weight and load capacity of your trailer, as well as its intended use. By understanding the different types of trailer leaf springs available, you can make an informed decision that best suits your hauling needs.

Factors Influencing the Choice of Leaf Springs

When it comes to selecting the appropriate trailer leaf springs, several factors come into play. These include the trailer weight and load capacity, the intended use of the trailer, and the leaf spring dimensions, among other things.

Trailer weight and load capacity

The weight of your trailer and its load capacity are key determinants in deciding the type of leaf springs to install. The capacity or weight rating of a trailer leaf spring is an essential factor to consider, as it determines the maximum load the spring can bear (Tow-Max).

Moreover, the number of leaves in a trailer leaf spring also directly affects its load-carrying capacity. Generally, more leaves indicate a higher-capacity spring. For instance, a leaf spring with six leaves would typically bear a heavier load than a leaf spring with four leaves.

Intended Use of the Trailer

The intended use of your trailer is another important consideration. For instance, a trailer used for transporting heavy machinery would require a different type of leaf spring compared to a trailer used for hauling lighter, everyday items. The choice of leaf spring material should ideally depend on factors such as trailer weight, load capacity, and intended use.

Leaf Spring Dimensions

Lastly, the dimensions of the leaf spring should match the existing spring, as these dimensions affect the fit and performance of the suspension system. This includes the length and width of the spring. A mismatch in these parameters could lead to improper suspension performance and could potentially compromise safety.

When choosing your leaf springs, it’s essential to consider these factors to ensure the safety and performance of your trailer. Remember, the right leaf springs will not only enhance your trailer’s performance but will also provide a smooth ride, irrespective of the load. For more information on trailer parts and accessories, check out our articles on trailer hitch locks, trailer brake controllers, and trailer safety chains.

Maintenance and replacement of leaf springs

To ensure the longevity and optimal performance of your trailer leaf springs, regular maintenance and timely replacement are essential. Here, we will dive into the signs of wear and damage, the importance of regular inspection, and guidelines for replacement.

Signs of wear and damage

Just like any other part of your trailer, leaf springs can wear out over time due to constant use, exposure to the elements, and road conditions. Warning signs that trailer leaf springs may need to be replaced include sagging or uneven suspension, excessive bouncing or swaying, and visible cracks or rust on the springs (etrailer.com). Ignoring these signs can lead to a compromised suspension system, resulting in an unsafe towing experience.

The importance of regular inspection

Given the integral role of trailer leaf springs in providing support and stability, regular inspection is non-negotiable. They help distribute the weight of the trailer evenly across all wheels, preventing excessive stress on individual components (HowStuffWorks).

To perform an inspection, start by visually examining the trailer springs for signs of wear, such as rust or cracks. Next, check if the trailer is sitting evenly when loaded. If one side appears lower than the other, it could indicate a worn-out leaf spring. Also, pay attention to the ride quality. If you notice excessive bouncing or swaying, it might be time for a replacement.

Replacement Guidelines

The lifespan of trailer leaf springs can vary depending on factors such as usage, the weight of the load, road conditions, and maintenance. On average, they should be replaced every 5-7 years or after approximately 10,000–15,000 miles (etrailer.com). However, keep in mind that these are just averages; your specific situation may require more frequent replacements.

When it comes to replacing leaf springs, we recommend seeking professional help. The process involves several steps and requires specialised tools. Moreover, incorrect installation can lead to serious safety issues. Therefore, it’s best to leave this task to the professionals.

Remember, leaf springs are just one component of your trailer’s suspension system. Don’t forget to maintain other parts like trailer wheel bearings, trailer hitch locks, and trailer brake controllers to ensure a safe and smooth towing experience.

Upgrading Your Trailer Leaf Springs

At times, the standard leaf springs on your trailer might not meet your specific needs, especially when frequently hauling heavy loads. In such cases, upgrading your trailer leaf springs can significantly enhance your trailer’s performance and longevity.

Reasons for Upgrading

There are several reasons why you might want to upgrade your trailer leaf springs. For instance, if you need to haul heavier loads, adding extra leaf springs to your trailer’s suspension can provide the additional support needed.

Upgrading to a higher-quality or heavy-duty leaf spring can also increase the load capacity and durability of your trailer. This allows it to handle heavier loads and tackle challenging road conditions better.

Improving the ride quality of the trailer is another reason for upgrading your leaf springs. With the right selection and installation, upgraded leaf springs can offer a smoother and more comfortable ride, particularly for trailers frequently used on rough terrain.

Selection and Installation Process

The process of upgrading your trailer leaf springs begins with selection. It’s crucial to pick the right type and size of leaf springs that are compatible with your trailer and meet your specific requirements.

When choosing your new leaf springs, consider factors such as the weight and load capacity of your trailer, the type of loads you typically haul, and the conditions of the roads you usually traverse. Different types of leaf springs offer different benefits, so it’s important to match your choice with your needs.

After choosing the right leaf springs, the next step is installation. This is a task best left to a professional trailer mechanic or technician. Proper installation is crucial for both the performance and safety of your trailer. An incorrectly installed leaf spring can lead to trailer instability and potential damage to the trailer and its cargo (etrailer.com).

In conclusion, upgrading your trailer leaf springs can greatly improve the performance, safety, and durability of your trailer. Whether you need to haul heavier loads, traverse rough roads, or simply improve the ride quality of your trailer, an upgrade might be just what you need. Remember, it’s always best to seek professional advice when considering such an upgrade to ensure you make the best choice for your needs and have the new springs correctly installed.

The Role of Trailer Leaf Springs in Safety

When it comes to the safety and stability of your trailer, trailer leaf springs play a significant role. These integral components of the trailer’s suspension system support the weight and absorb shocks and vibrations during travel, contributing to a smoother and more controlled ride.

Weight Distribution and Stability

One of the key functions of trailer leaf springs is to distribute the weight of the trailer evenly. This feature ensures that the weight is evenly distributed across all axles, preventing excessive stress on any one axle and contributing to the overall stability of the trailer.

By distributing weight evenly, leaf springs help prevent load shifting, which can lead to dangerous trailer sway or tipping. This even weight distribution also ensures that all tyres share the load equally, reducing wear and tear and extending tyre life.

Maintaining stability is crucial, especially when towing heavy loads on uneven terrain or in adverse weather conditions. When paired with other safety equipment, such as trailer safety chains and trailer brake controllers, the safety benefits of leaf springs are even more significant.

Impact on the Trailer Frame and Cargo

Aside from weight distribution and stability, trailer leaf springs also reduce the impact on the trailer frame and cargo. The springs flex to absorb shocks and vibrations, providing a smoother ride and protecting the frame and cargo from damage.

This shock-absorbing feature is particularly important for trailers carrying delicate or valuable cargo. The reduced vibrations mean less risk of damage to the items being transported.

In conclusion, trailer leaf springs are crucial for maintaining trailer safety and stability. They play a significant role in weight distribution, shock absorption, and cargo protection. Therefore, regular inspection and maintenance of your trailer’s leaf springs are essential to ensuring safe and smooth towing experiences. For more information on trailer maintenance and safety, explore our other guides on topics like trailer wheel bearings and trailer backup cameras.

Lifespan of Trailer Leaf Springs

Understanding the lifespan of trailer leaf springs is crucial in maintaining the safety and performance of your trailer. In this section, we’ll discuss the factors affecting the lifespan of trailer leaf springs and provide guidelines on the average lifespan and replacement frequency.

Factors Affecting the Lifespan

Several factors can affect the durability of trailer leaf springs:

- Usage: The frequency and manner in which the trailer is used can impact the lifespan of the leaf springs. Regular, heavy-duty usage can lead to faster wear and tear.

- Load Weight: The weight of the load the trailer carries, particularly if it frequently carries loads near its maximum capacity, can cause the leaf springs to wear out faster.

- Road Conditions: Driving on rough or uneven roads can put additional strain on the leaf springs, leading to quicker degradation.

- Maintenance: Regular inspection, lubrication, and maintenance of the leaf springs can significantly extend their lifespan. This includes checking for any signs of damage or wear and making necessary adjustments (etrailer.com, USA Trailer).

Average Lifespan and Replacement Frequency

On average, trailer leaf springs should be replaced every 5-7 years or after approximately 10,000–15,000 miles, depending on their condition and the factors mentioned above.

| Lifespan Period | Mileage |

|---|---|

| 5 to 7 years | 10,000–15,000 miles |

However, it is important to regularly inspect your trailer leaf springs for signs of wear, such as cracks, corrosion, or sagging. If any of these signs are evident, you should replace the leaf springs immediately to maintain the safety and performance of the trailer.

In conclusion, the lifespan of trailer leaf springs is variable and depends heavily on usage, load weight, road conditions, and regular maintenance. By understanding these factors and keeping a diligent eye on the condition of your leaf springs, you can ensure the longevity of your trailer’s suspension system and the safe operation of your trailer. For more information on trailer maintenance and safety, check out our articles on trailer backup cameras, trailer brake drums, and trailer safety chains.

Author

I am Rahatul Ashiq Tamal. Another author of Muscle Trailers. Muscle Trailers is a well-known trailer brand in Sydney, Melbourne & Adelaide

How to Mount a Spare Tire on Your Trailer: A Simple Step-by-Step Guide

Trailer service centers receive over 1 million phone calls and 1.3 million emails each year about trailer maintenance problems....

How to Fix RV Roof Leaks: Simple Roof Leak Detection Guide for Beginners

Did you know DIY RV roof repairs can cost under $50? But undetected leaks could lead to substantially higher repair...

Starting a Food Truck Business in Australia: From Trailer Selection to Launch

The Australian mobile food market has evolved into a billion-dollar industry. This makes a food truck...